Precision and safety are the twin pillars that uphold the aerospace industry. In the world of aerospace manufacturing, even the smallest component plays a critical role in ensuring the safety and reliability of aircraft. This is where bearing proof-load tools step in. In this article, we’ll delve into the significance of these tools in aerospace manufacturing and highlight the expertise of Smith Machine and Tool.

Understanding Bearing Proof-Load Tools

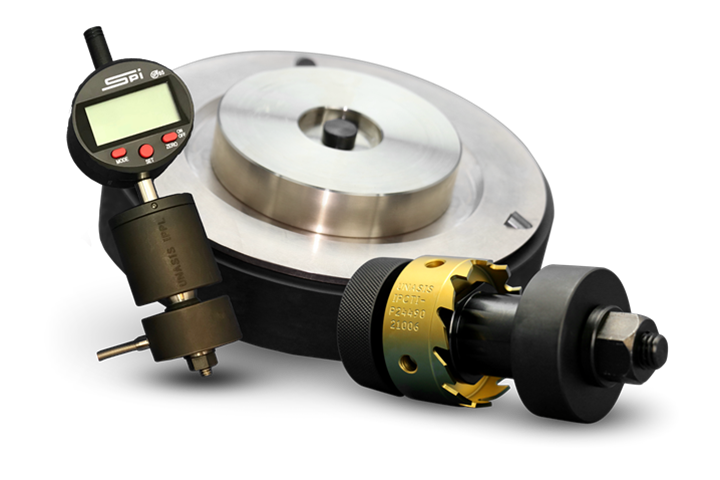

To comprehend their importance, let’s start with what bearing proof-load tools are. These specialized tools are designed to do one thing exceptionally well: test the integrity of components, particularly bearings, which are the unsung heroes of aerospace machinery.

The aerospace industry demands components that can withstand extreme conditions, from rapid changes in temperature to high-speed rotations. These tools ensure that these components meet or exceed the stringent safety and performance standards.

The Crucial Role in Aerospace

In aerospace manufacturing, precision is everything. The smallest deviation from the design specifications can have far-reaching consequences. This is where bearing proof-load tools become indispensable. They are the gatekeepers of quality and safety.

Imagine an aircraft engine. It consists of countless bearings, each with a specific role to play in ensuring the engine’s smooth operation. These bearings must endure immense stress and pressure. Bearing tools rigorously test these components to verify that they can withstand the demands placed upon them.

For aerospace manufacturers, the use of these tools is non-negotiable. Components that fail to meet the required standards pose a significant risk. Ensuring that every part is up to the task is paramount in maintaining the highest level of safety.

Benefits of Using these Tools

Why should aerospace manufacturers invest in bearing proof-load tools? The benefits are clear and far-reaching.

- Enhanced Safety: Safety is the primary concern in aerospace manufacturing. These tools ensure that every component meets the necessary safety standards, reducing the risk of catastrophic failures in flight.

- Reliability: Aerospace components must operate flawlessly, and reliability is paramount. These tools contribute to creating components that function consistently under extreme conditions.

- Cost-Effectiveness: Catching flaws and weaknesses early in the manufacturing process is more cost-effective than dealing with failures during testing or, worse, in the field. These tools save both time and money.

- Quality Assurance: Aerospace manufacturers must adhere to the highest quality standards. Bearing proof-load tools provide assurance that components are built to meet or exceed these standards.

The Role of Smith Machine and Tool

When it comes to bearing proof-load tools, choosing the right manufacturer is crucial. “Smith Machine and Tool,” located in Huntington Beach, CA, is a trusted name in this field.

Their commitment to quality, precision, and innovation makes them a valuable partner in aerospace manufacturing. Smith Machine and Tool understands the unique demands and rigorous standards of the aerospace industry. Their expertise in producing high-quality bearing tools has earned them a stellar reputation.

Conclusion

In the aerospace industry, safety and precision are non-negotiable. Each component must meet the highest standards to ensure the safety and reliability of aircraft. Bearing proof-load tools are the unsung heroes in this endeavour, rigorously testing components to verify their integrity. Investing in these tools is not just a choice; it’s a necessity. Aerospace manufacturers that prioritize safety and quality turn to manufacturers like Smith Machine and Tool for bearing proof-load tools that uphold the industry’s highest standards.